Do you need a prep station or a limited finishing station?

The answer is “it depends”.

First you have to ask yourself a few questions about the intended work that will take place in the work area.

What are you doing in the work area? Is it just automotive sanding and vehicle prep before bringing it into the paint booth? Or do you intend to spray primer or paint in the work area also?

Automotive Prep and Sanding:

If the answer is that you strictly intend to sand and prep vehicles in a certain area of your collision repair facility, then you can install an automotive prep station. Operations that include vehicle sanding and prep only (no spraying paint or primer of any kind) allow you to use a simple prep station with exhaust and no further requirements. As a side-note if a prep station is what you need, make sure it is a recirculating prep station.

Prep stations may solve your problems of too much dust and debris, but may cost you thousands if the fan or fans are exhausting to the outdoors and have no option for recirculation. In this case, conditioned shop air (either heated or air conditioned) is thrown outdoors and can add up to high utility bills. Make sure you see re-circulating on the products spec sheet or make sure you understand the way it works before you purchase it.

Limited Finishing:

If you intend to spray in the prep station work area, an exhaust-only automotive prep station will not suffice. As soon as any priming or paint spraying is going on, a limited finishing station is necessary by code.

A limited finishing station is a different tool than a prep station. Among others, a limited finishing station must include three main features that differentiate it from a typical automotive prep station.

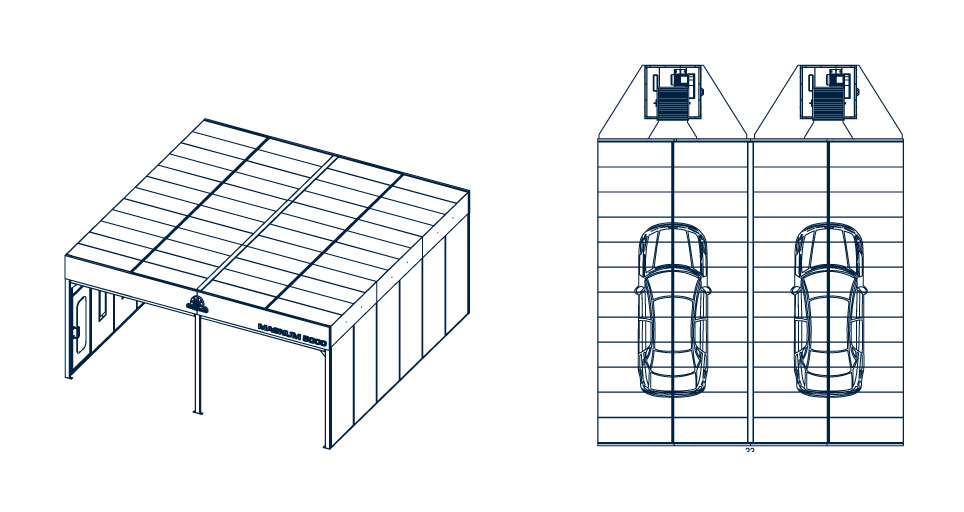

1. A Full Roof (Closed Top or Ceiling) – This is for containment. Typically including light fixtures and filters, you will see the roof either free standing (supported by walls that make up the limited finishing station work space) or as ceiling or roof plenums hung from cables that attach to the shop ceiling.

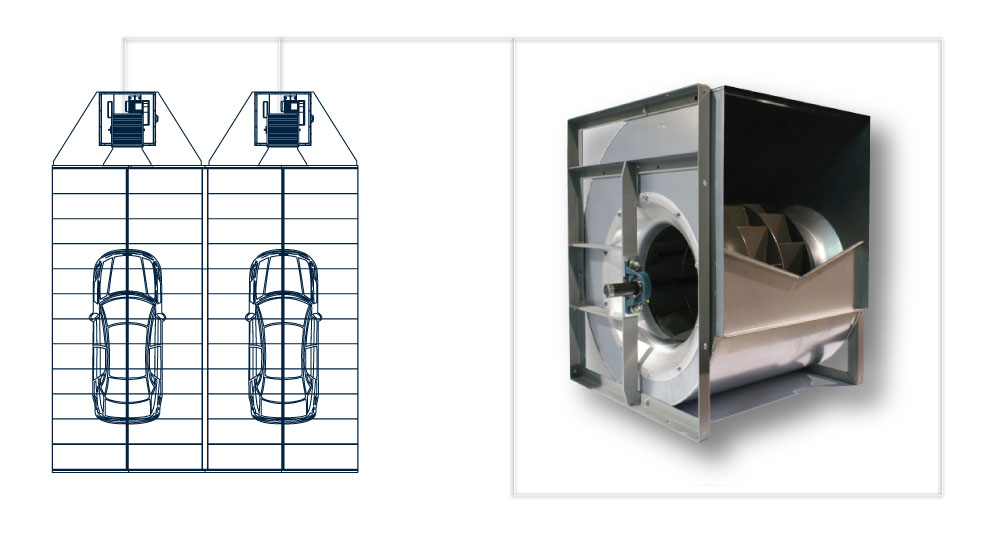

2. Dedicated Intake Fan – A limited finishing station differs in regards to an automotive prep station in that it must provide a dedicated intake fan. This is to ensure that the paint over-spray or contaminants are not drawn back into the limited finishing station’s work space.

3. Containment (Curtains or Walls) – A limited finishing station is required to have a partition on at least three sides of the work space. These partitions can be non-combustible curtains or walls.

Limitations of Spraying:

Although a limited finishing station meets code for spray application, it is not a paint booth. It is classified as “limited finishing station” which means no more than 1 gallon of material is to be sprayed in an 8 hour period. Spraying of more than 1 gallon of paint or coating material per day requires the installation of a fully enclosed paint booth.

Code Reference:

Below is the code referenced in determining the requirement of a limited finishing station over an automotive prep station.

NATIONAL EMISSION

STANDARDS FOR

HAZARDOUS AIR

POLLUTANTS

NESHAP

(SUBPART HHHHHH)

A direct link to NESHAP HHHHHH info is here. Read up to understand the requirements for limited finishing and unlimited finishing. You can also read up on many different practices recommended and required by the EPA regarding collision repair facilities at the EPA Collision Repair Campaign section of EPA.gov.

Recap:

Overall, the rule of thumb is that if you are going to be doing spraying of any kind, you should look into a limited finishing station instead of a prep-station. Please know that other restrictions and many codes regarding automotive prep stations, paint booths, and/or limited finishing stations may apply depending on building layout and requirements by local authorities. The best thing to do on any new project is to talk to an experienced finishing equipment professional in your area. They should be able to understand your needs and look at the intended equipment installation area and explain the applicable codes and permits associated with installing a paint booth, prep station, or limited finishing station.

Hope this helps some of you out there. For more info or if you have questions, please post a comment or contact accudraft directly