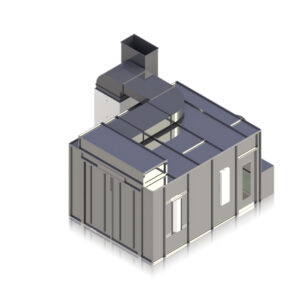

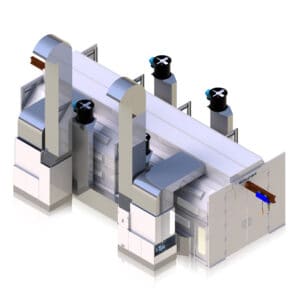

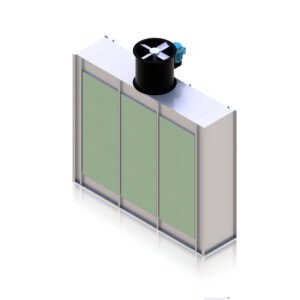

The Accudraft industrial curing oven provides a clean environment for baking and curing parts after the paint application process. High temperature rated fans provide slow and consistent hot air to the cabin, while insulated wall panels ensure the heated air is contained and safe to the touch outside. Hot air is exhausted through insulated ducts before traveling through regular duct work outside. Thick insulated doors provide easy access to inside the oven and allow parts to be brought in and out quickly. Ovens can be paired with a part prep area for sanding, priming and painting.

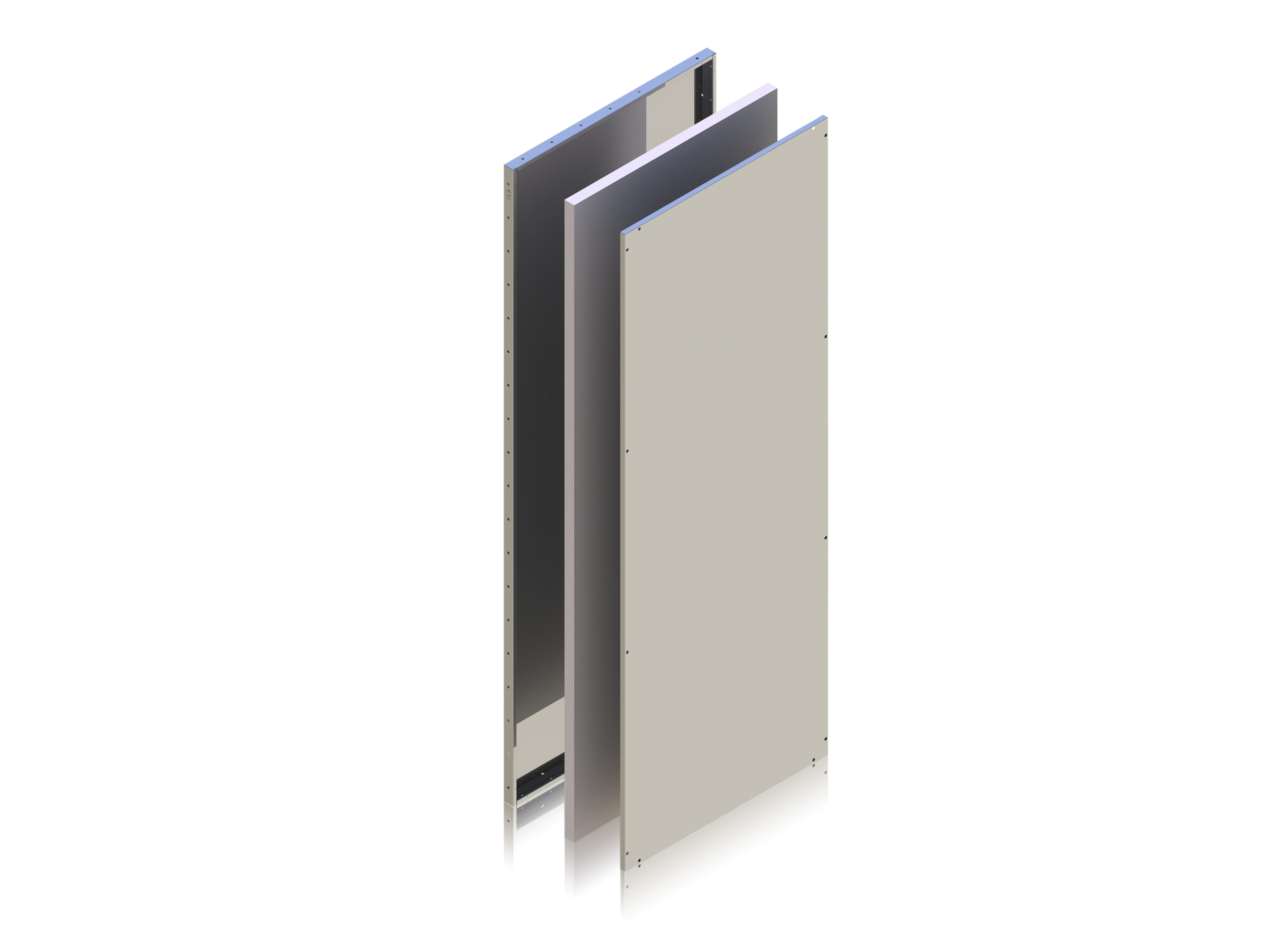

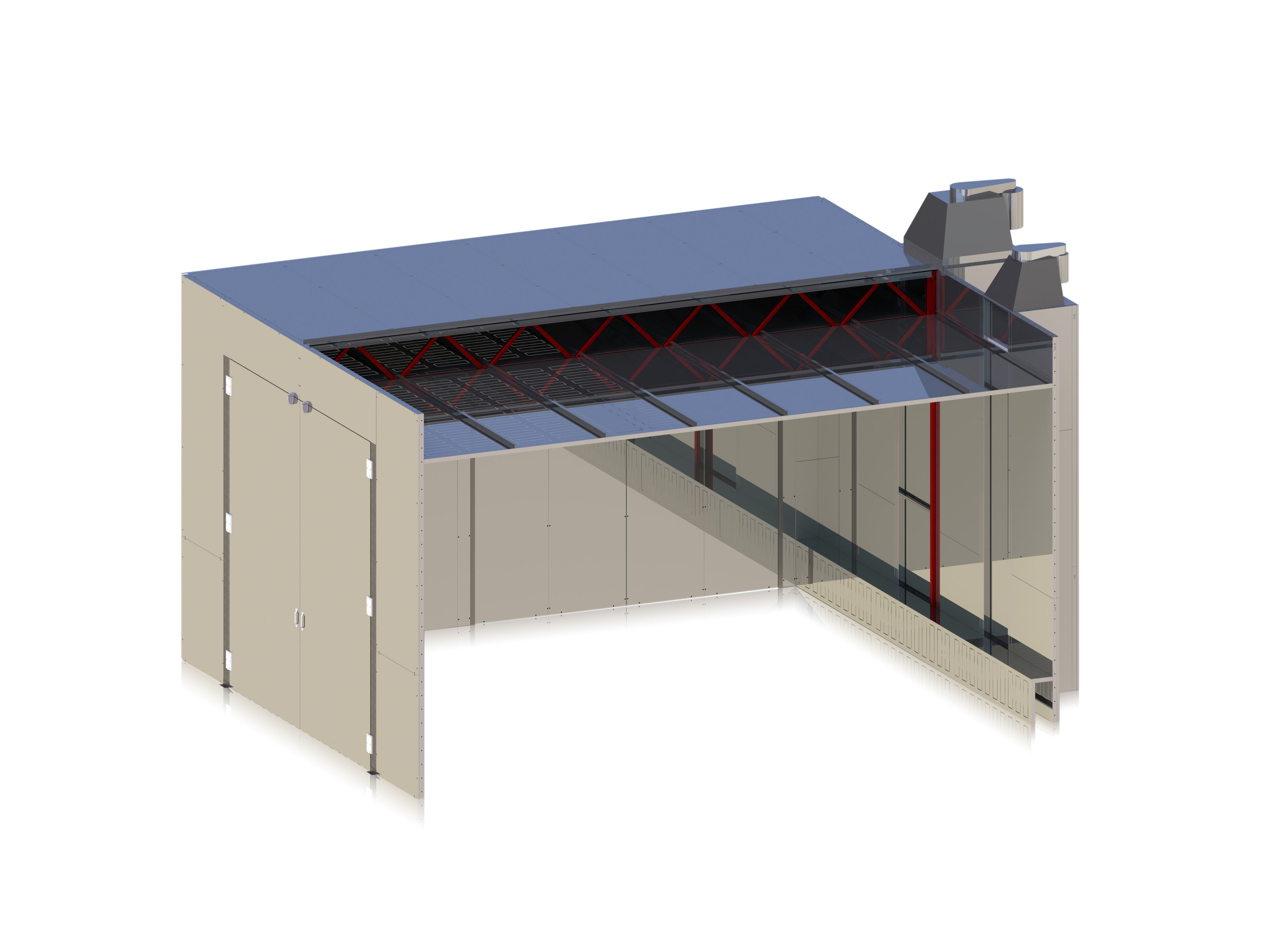

Dual Skin Insulated Construction

Galvanized steel on the inside and outside of the cabin with thick non-flammable insulation between the wall panels.

Steel Reinforced Framing

Heavy tube steel construction provides support and rigidity to the structure of the oven. Steel is welded and holes are pre-drilled for easy assembly.

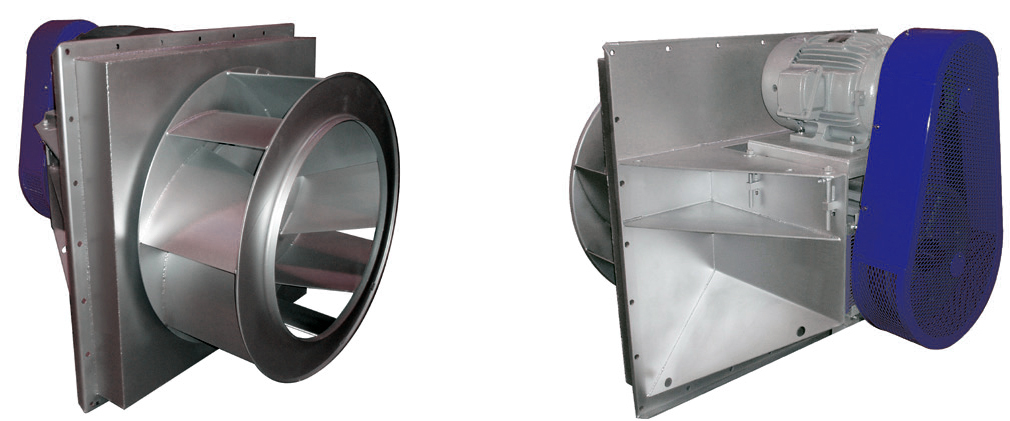

High Efficiency Plug Fans

BEPL plug fans feature backward curved, non-overloading, single thickness airfoil type wheels that provide efficient airflow to the cabin. Fans can be mounted horizontally or vertically, allowing flexibility during design and installation. The high temperature rating of these fans make them perfect for heating your curing oven and exhausting the hot air safely. Insulated plug protects motor and drive components from heat, while spark resistant construction prevents problems when handling potentially explosive particles, fumes or vapors.

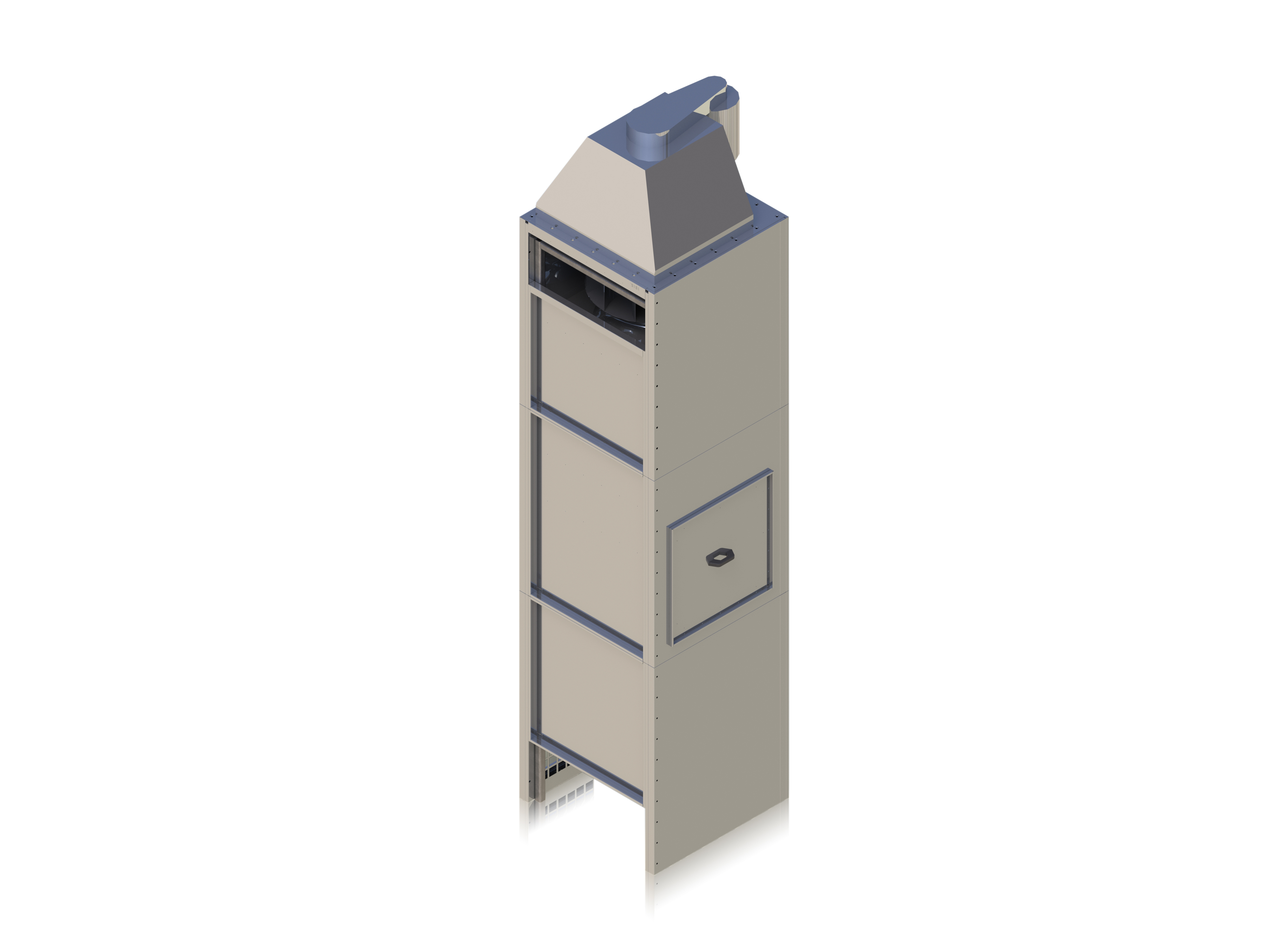

Insulated AMU

The heated air makeup on the curing oven is insulated and safe to the touch both inside and outside the cabin. Fresh air is drawn from filters at the AMU’s base and passed through the burner cabinet where it is heated to the desired temperature for baking and curing.

SmartPad™ Digital Controls

Accudraft’s SmartPad™ digital control panel provides the user with all process information and settings in one compact and easy to read control unit. Fan speed, temperature control and more can be adjusted and monitored simply with the SmartPad™ system.