Whether you are just curious about the process of powder coating or looking into elevating your shop with state-of-the-art equipment to make powder application efficient and easy, then this post is for you. Powder coating is a multi-step finishing process that involves cleaning and preparing the item, coating it with a fine powder and then curing it with high heat. Powder application and curing creates a very durable and beautiful coating around a product once the melted powder cools and hardens. This guide to powder application and curing will highlight and explain how to prepare a product for the process, the best equipment for this job and how to ensure flawless results for every finish.

Preparing for Powder Application

To achieve the best results with powder application, the product needs to be clean and free of dust, debris, rust, old paint or any other type of material. Anything that is left on the surface prior to application can affect how the powder adheres and the durability of the finish. In order to prepare a product for powder application, you can pretreat it to ensure that it is as clean as possible. For this step you may look into a prep station – a dedicated space to clean, sand and prepare a product for powder application. We have four different prep station models designed to create flawless paint jobs for all levels of business:

- The Magnum5000 Prep Station is our top of the line freestanding prep station, and an ideal solution for high volume shops looking to speed up the process.

- The Prep4000 Prep Station is great for shops that have limited space, and it can be used to both prep and paint.

- The Prep3000 Prep Station is perfect for collision repair centers that use paint booths for vehicle parts, bumpers and smaller jobs.

You can also use additional upgrades like the Accudraft Duct Collection System to keep the area free of particles and debris. These powerful systems provide strong airflow that directs particles into the filtration cabinet as well as downward-facing baffles that keep heavy particles from entering the filters.

Powder Application

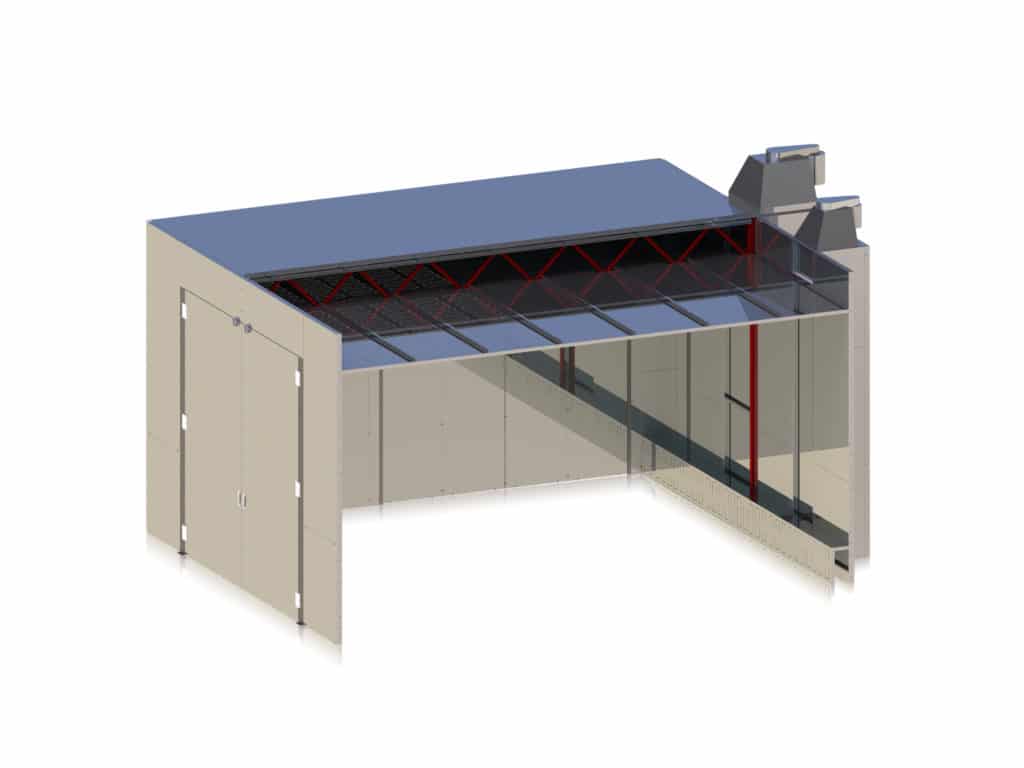

Once the product is prepped for application you will need a powder spray gun. This special tool uses compressed air that blows powder out of the gun as it is applied to the surface of the product. Any leftover powder that doesn’t stick to the product is referred to as overspray, which is why a professional paint booth is necessary. A paint booth is designed to keep the rest of your shop clean while providing a well-lit area for you to apply powder coating. There are various paint booth configurations to choose from, and the ideal booth for your shop depends on what types of products you work with, how much space is available for the equipment and your workflow requirements. The Accudraft Pro Series powder application booths utilize strong airflow and proper lighting to give the painter the ideal conditions to work in. Accudraft also offers a Pro Series recirculating powder application booth, which provides a much cleaner environment by fully enclosing the process and recirculating the air back to the workspace. Powder application booths can be simple, non-recovery systems that simply filter out the overspray, or they can be fully contained, recirculating booths with cartridge filters made for recovery of unused powder.

The Curing Process

Once the product you’ve been working on is powder coated, the final step is to place it in a specially designed powder curing booth. This equipment provides fast curing of coatings with high temperatures – usually between 325O and 450O Fahrenheit. The insulated construction and recirculating airflow in Accudraft powder curing booths lets the user reach curing temperatures quickly and efficiently. The coated product is exposed to the high heat for a set period of time, and once the process is complete, the product will be allowed to cool before being handled again.

Powder coating is a process, but it provides a high-quality, attractive and durable finish. Powder coated products are more resistant to various environmental factors like moisture, chemicals and extreme weather conditions, which reduces the risk for chipping, scratches, corrosion and other wear-and-tear issues. Choosing the ideal equipment for your business can be a tough decision to make, especially when there are so many options to choose from and each option provides different benefits. If you are thinking about adding a prep station, paint booth or other professional equipment to your shop, but you are not sure what to choose – contact your local Accudraft distributor. We would be happy to answer any questions you may have as well as offer personalized solutions for your unique business.