One of the most misunderstood factors of paint booth operations is temperature settings and control – recommended temperatures for painting in a spray paint booth, and how important temperature control is in the overall painting process.

Since the answer can vary greatly depending on many factors, such as the type of coating that you are using, there isn’t a “one size fits all” answer to this question. Even though there is no easy answer to the question, there are some good general guidelines that will help give you a better idea of what your average temperature settings for your paint booth should be.

Paint Booth Temperature Control Done Right

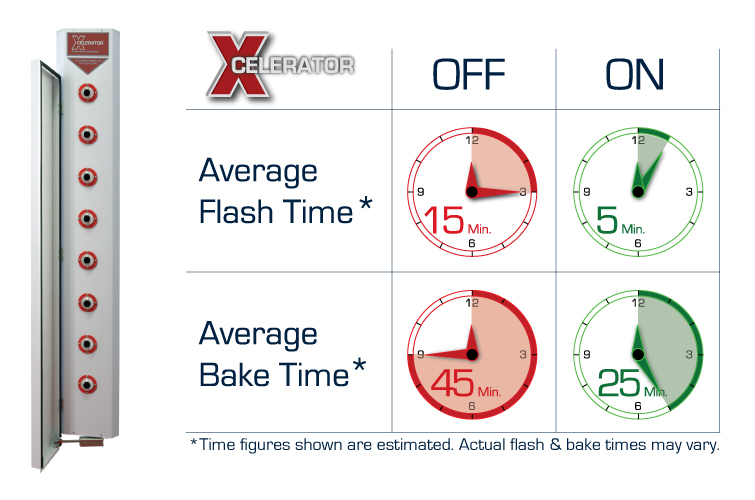

Generally speaking, an automotive spray paint booth must be at least 55 degrees if you are using any automotive paint with a catalyst, in order for the paint to dry. Automotive paint companies base the overall time it takes their product to flash, cure, recoat, etc on an industry standard of 70 degrees and 50% relative humidity, or RH. There is a generally accepted rule of thumb in the spray paint booth industry – for every 15 degrees above 70 degrees, the paint or coating will dry twice as fast. Conversely, the opposite is true – for every 15 degrees below 70 degrees, the paint or coating will take two times as long to cure.

However, this is only true until you get down to 55 degrees, as we mentioned earlier. At any temperature below 55 degrees, the catalyst will go dormant and will not crosslink, meaning that one polymer chain will not bond to the other. It is important to note that once the catalyst goes dormant, it will never crosslink properly.

This principle perfectly demonstrates exactly why paint booth temperature settings are so important. Clearly, heat plays a huge role in the overall productivity of a shop – it can allow more that twice the work to go through a shop on a daily basis, increasing your profits and bottom line.

Automotive spray paint booths are available in both heated and non-heated models. If you choose to go with a non-heated paint booth, it is important for you to keep in mind the amount of heated air that is exhausted from a heated building. It is possible for your non-heated booth to displace and move more air than your building’s heating system can keep up with, rendering your building unable to maintain a consistent temperature.

If you are going to be using your spray paint booth for automotive applications, your paint booth temperature settings will be slightly different. The average temperature required to cure paint is between 65 and 70 degrees, and as with automotive applications, determining the correct temperature setting can be a bit more difficult.

First and foremost, you want to look at the type of coating you are using. No two coatings are alike, and the list of coating surfaces is incredibly long. Additionally, the same type of coating can vary from manufacturer to manufacturer. For these reasons, it is easy to see where some of the confusion comes in.

You will also need to consider the size and type of object that you are painting, as this will also greatly impact how long the item will take to dry, and therefore, also the temperate settings that should be used. The relative humidity will also need to be taken into consideration when deciding temperature settings, since the higher the level of relatively humidity, the longer the object or item will take to dry.

Essentially, this is all to say that there is not one right or recommended paint booth temperature setting. However, knowing the factors that contribute to the decisions will help you to determine which settings are best for you. To be safe, you can always check with the manufacturer, as they will be able to give you an exact temperature setting to properly dry and cure your coating.

About Accudraft

Accudraft was founded in 1977. Over the course of the past 37 years, Accudraft has grown into the world’s leading spray booth manufacturer and a worldwide innovator in paint booth technology.

Our strong commitment to quality produces some of the best and longest lasting finishing systems, used for different applications in various industries, including:

- Automotive finishing

- Truck finishing

- Industrial finishing

- Aerospace finishing

- Marine finishing

Please take a look around our website to learn more about the products and services that we offer. If you have any questions or if you would like to discuss the specific needs of your shop, please feel free to give us a call!