If you’re looking for a paint booth setup that boosts your productivity and decreases the amount of time it takes to finish a paint job from start to finish, you’re going to need a good drying system. Purchasing a heating system that recycles air is one of the best investments that a paint booth owner can make, especially for small business owners who need to increase productivity and cut back on energy expenses.

Investigate Before You Buy

While it’s certainly true that heat recycle systems have become the norm in paint booths, that doesn’t mean that you should assume that every booth comes with modern heating systems. Some manufacturers only add heat recycle systems when specifically requested to do so, and this means that you could end up buying a paint booth that’s literally wasting heat. This results in you spending more time and money to complete an operation that a modern heating system could finish with ease.

If you’re in the market for a new paint booth, it’s important that you do some research before finalizing your purchase. Have a look at customer reviews and see what other owners have said about heating options and don’t allow yourself to become fooled by labels like “air mixing”, “air slow down”, “air recirculation”, or other types of attention-grabbing terms. None of these advertised features mean anything if the paint booth doesn’t have a properly certified air recycle system, so always ask the manufacturer or sales representative if their paint booth provides around 80%-20% recycling capabilities.

Options for Recycling Heat in Your Paint Booth

Options for Recycling Heat in Your Paint Booth

Now that you know a little bit about what to look for in a heating system, let’s cover the two different systems options that you can use for your paint booth.

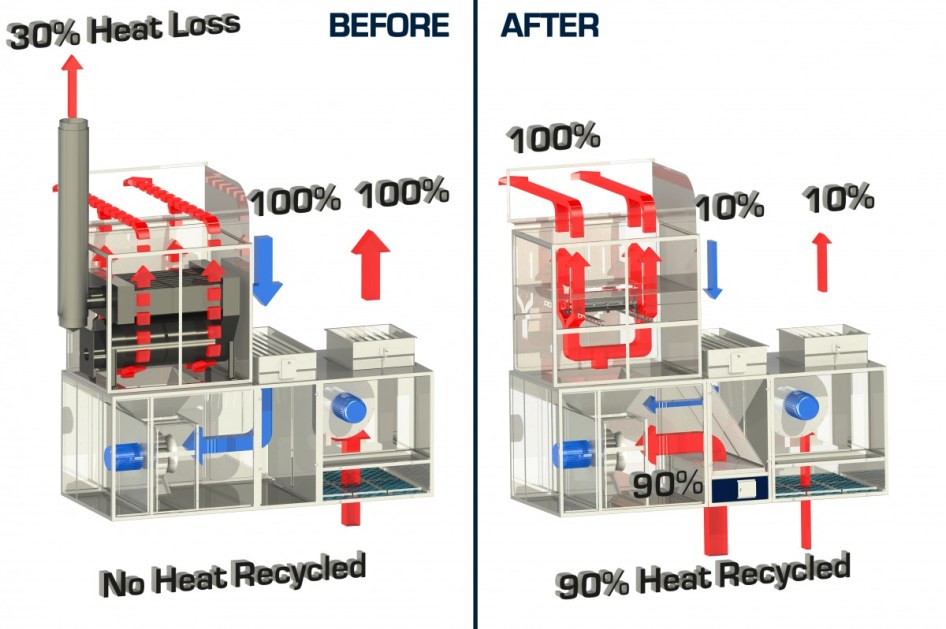

1. Indirect fire heating

Indirect fire heating systems run best on diesel and oil, but work with gasoline as well. Unlike other heating systems, the indirect fire system requires a chimney in order to function. The benefit of the indirect fire heating system is that it’s effective and can quickly get the job done, and it’s the best type of heating system for owners who’re looking for a something that’s built for recycling heat. Since this type of heating system uses a chimney, you can expect to lose as much as 30% of the heat, making this type of heating one of the less efficient paint booth systems.

2. Direct fire heating

With advancements in paint booth heating technology, direct fire heating systems are a great way to utilize a booth by recycling heat. This type of heating system is similar to the indirect fire heating system except that doesn’t require a chimney in order to run. The result is a heating system that’s better at recirculating hot air during bake cycles. In fact, a good direct fire heating system has a recycling heat rate of around 90%. That translates into faster bake times and anywhere between 30% to 60% savings in energy costs.

Should I Make the Switch to Direct Fire?

There are a number of excellent benefits that come with using a direct fire system for your spray booth. It’ll reduce your bake times, which translates into more productivity, and will also cut back on the amount of money you spend on energy every month. In addition, most direct fire heating systems can retrofit older paint booths, making the installation process quick and easy. So why wouldn’t anyone want to scrap their indirect fire heating for a system that’s designed specifically for recycling heat?

The primary reason some shop owners don’t make the switch is because of money. While it’s undeniable that a direct fire heating system will save you a lot more money in the long run, they can be expensive to install; especially on bigger booths for trucks and industrial equipment, which may require additional ductwork before switching the systems. In addition, the process of converting over to a direct fire system takes an average of two days to complete, and some smaller body shop owners just can’t afford to suspend their operation for two days.

If you’re interested in making the switch and are worried about the up-front cost and downtime that comes with the installation, it might be a good idea to start a savings plan months before you plan on making the switch. That way, you can weather the downtime and get back to running your paint booth without feeling any unnecessary stress.

The Benefits of a Heat Recycle System

Changing over to a direct fire system may be one of the best purchasing decisions you can make as a business owner. If you’re converting an old heating system to a heat recycle system, the money spent on your installation can be made up in a few months; if you’re buying a brand new paint booth, you’ll be happy to know that the cost of a direct fire system is more or less the same as an indirect system, so there’s no reason not to switch to a more energy efficient model.

Here are some of the benefits you’ll get from a direct fire system:

- Cleaner combustion, which makes for a safer workplace environment with better air quality

- Higher air temperature that makes paint dry at a much faster rate

- Better temperature control

- The chance to save as much as 30% of your monthly fuel spending

In addition, the direct fire heat system comes with a number of optional features to enhance your performance, including the SmartPad and EnergySmart systems, which enable to you make modifications to airflow, drying cycles, and a number of other settings from an easy-to-use computer program.

Overall, heat recycle is an incredible technological advancement that has revolutionized the painting industry. By using downdraft pit tunnels or duct connections, the heating system is able to recirculate the air from the workspace, which means that approximately 80% to 90% of the heat is reusable.

Your Booth’s Temperature Settings Matter

Running a paint booth with an old heating system or no heat system at all will greatly inhibit your productivity and can even affect the quality of your work. In fact, maintaining a stable temperature inside your booth is one of the most important factors in determining how fast your items dry and how they look after the painting cycle is complete. If you’re thinking about upgrading your heating system to cut back on time and increase your productivity, you may want to look into fitting your booth with the Xcelerator Paint Drying System as well.

The Xcelerator has jet modules that spray air and heat into your freshly painted item, causing it to dry much faster than usual. In fact, it can reduce your average flash time down to about five minutes and cut your bake times in half. The drying system is completely customizable and can be integrated into the SmartPad controls or fitted with an in-booth control panel. It can even cut your energy expenses in half, making it an excellent tool to have for body shop owners working with waterborne paints.

Making the Switch to a Heat Recycling System

You’ll need to get a permit before you add a heat system to your paint booth system. Adding a new heat system or converting an older model to a heat recycling system is a complex operation and should only be done by experienced professionals. If ready to make the switch to a better heat system, consider contacting Accudraft to find a licensed professional in your area. The conversion process is quick and easy, and within a couple of days, your new paint booth will be up and running.

Accudraft also has a number of new paint booths and paint booth accessories to help you get the most out of your operation. All of the paint booths are equipped with state-of-the-art heating systems that have been designed to increase productivity without putting too much of a strain on your energy expenses.

You may also want to consider adding a Variable Frequency Drive, or VFD, to your paint booth alongside your heat recycling system to further reduce the amount of money you spend on running your paint booths. Installing a VFD gives you the opportunity to regulate heat and energy expenditure more efficiently, and even has a number of different economy settings that can help you save a few thousands of dollars over the course of a year.

There’s No Job Too Big or Too Small

Regardless of what you line of work is, Accudraft has the equipment available to accommodate you so that you work smarter, not harder. Accudraft is the industry leader in automotive, industrial, and aerospace paint booths. Have a look at some of their popular models, like the Titan and Italia booths, or arrange to have a custom paint booth and prep area built just for your workspace. To learn more about how Accudraft can help you get the best paint booth system for your setup, contact one of our professionals today.