Having an automotive prep station can speed up your productivity and help you work more efficiently. However, an automotive prep station isn’t for everyone who works with cars and trucks. Installing one in an existing workshop can become very expensive. Additionally, it will take a lot of electricity to power the station’s ventilation system. With that said, these stations can be a blessing for many people with body shops.

Why Should I Get an Automotive Prep Station?

If you want to limit the chances of dust and debris contaminating your paint by designating a specific spot for sanding and prep, then an automotive prep station is the right choice for you. Remember, most prep stations don’t allow for painting or adding primer. However, with a few minor modifications, all of the Accudraft automotive prep stations can be transformed to limited finishing stations.

If you work in collision repair, having a prep station that allows for limited finishing is a valuable tool. You can then prep, sand, prime, and paint in the same convenient location. The automobile never leaves the workshop during the process, which means that it’s protected from outside contamination at all times.

Maximize Your Productivity with MAGNUM

The Accudraft MAGNUM 5000™ is an extra-large automotive prep station designed for body shops that work on a larger scale. It comes with double bays, which are divided by heavy-duty curtains, and it can even be customized to additional work stalls. This makes the MAGNUM 5000™ ideal for companies that work with a high volume of automobiles.

The MAGNUM 5000™ works as a prep and limited finishing station when you choose to add the optional KD™ Series Integrated Air Makeup System. This means that you can do all of your sanding, prepping, and spraying in one location.

The KD™ Series Air Makeup unit has integrated heat, exhaust, and intake systems that are designed to boost the productivity and efficiency of the workshop. Your automotive prep station becomes a versatile work area that is capable of doing two jobs simultaneously: prepping and painting. In addition, the KD™ Series unit helps you save money and cut back on energy usage by recycling the air it uses.

MAGNUM Ensures a Debris-Free Work Area

One of a prep system’s primary functions is to remove all dust particles and paint chips from the automobile and work area. An exhaust system that isn’t powerful enough to clear your work stall places your job performance at risk.

The exhaust system that comes with the MAGNUM 5000™ is powerful enough to suck up any thick debris and paint buildup. It’s heavy duty and is able to handle a large workload without breaking or wearing down.

The exhaust system that comes with the MAGNUM 5000™ is durable and made to last for decades of use. Every work bay comes equipped with its own exhaust unit that works independently, so you don’t have to worry about the exhaust system becoming overburdened from heavy use. This makes the MAGNUM 5000™ a top-choice prep station for people who work with a high volume of automobiles.

Highlights of the MAGNUM 5000™

The MAGNUM 5000™ is built with industrial strength parts that can withstand heavy use. This makes it an ideal choice for collision centers and body shops that deal with multiple automobiles a day. Here are some of the benefits you get with the MAGNUM 5000™:

- The option to add a direct or indirect heating system.

- A SmartPad Digital PLC control panel can be added to automate your system and help customize features like temperature and airflow.

- It comes with a durable control panel that can withstand thousands of hours of work without failure.

- Up to four working stations can be added.

Turn Your Workshop into an Assembly Line with the PREP 4000™

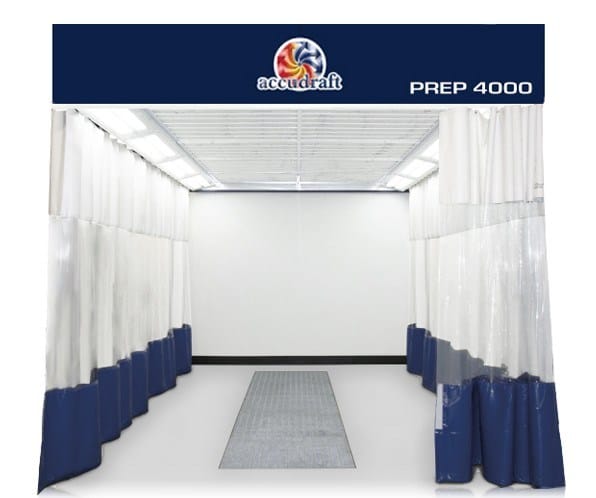

The Accudraft PREP 4000™ is a fully customizable prep station that’s able to provide a number of functions. The PREP 4000™ comes standard with a single work bay, but you have unlimited expansion capabilities. This means that you can add as many bays as you need to run your business.

Additional work bays are added to the side of the prep station and are separated by partitions. You have the choice of using metal walls or heavy-duty curtains to divide each bay.

Another interesting feature that comes with the PREP 4000™ is the option for a drive-thru configuration. This lets you take the automobile directly from the prep station to the paint booth without ever leaving the work area. Along with speeding up the process, this also prevents outside contamination and helps ensure a successful paint job.

The PREP 4000™ Meets all Expectations

If you’re looking for an automotive prep station that is well rounded and versatile, meet the PREP 4000™. You can choose to customize the station to fit the specific needs of your company. You have the option to expand or install additional features anytime so you’re able to upgrade the PREP 4000™ as your business increases.

The PREP 4000™ utilizes an exhaust system that recirculates air during prep, thereby reducing the amount of energy consumed. You also have the option of adding the AccuHz™ Energy Saving VFD System to your automotive prep station. This will greatly reduce the amount of money spent on energy each month, which is great for large and small businesses.

The PREP 4000™ comes with a powerful two-stage filtration system that removes dirt and reduces overspray. It also has a KD™ 500 series air makeup unit, making the station ready for limited spray. All you need to do is install a heating system and SmartPad™ control unit, and then you can start spraying in your work bay.

Highlights of the PREP 4000™

Here are some of the features that set the PREP 4000™ apart from other automotive prep stations:

- An unlimited number of work bays can be added at any point.

- It can come with a pitless or pitted design.

- It’s built with a heavy-duty vinyl interior and exterior.

- You have a number of optional features available to increase your prep station’s functionality.

Overall, the PREP 4000™ is a great station for businesses of all sizes. You have the option of installing the prep station in a way to give you exactly what you need, and you can increase its functions as your business grows.

Don’t Have a Heavy Workload? Try the PREP 3000™

If you want an automotive prep station but you don’t need a setup designed for multiple vehicles, the Accudraft PREP 3000™ is just what you need.

The PREP 3000™ comes as a compact single bay, making it perfect for workshops that are tight on space. Though small, the PREP 3000™ has a powerful floor and ceiling filtration system designed to remove dust and debris at 98% efficiency.

The PREP 3000™ Is Perfect for Light Work

If you need an automotive prep station to help you work on individual parts of a car or truck, the PREP 3000™ is right for you. It doesn’t take up the space of the full-sized workstations, and you’ll spend a fraction of the price in utilities.

The PREP 3000™ station comes with a powerful exhaust and recirculating air system that supports spraying. If you want to convert your prep area into a limited finish station, simply add a heating system and SmartPad™ control unit. This will let you use your prep area for spraying and baking cycles, which is perfect if you’re working with parts that don’t require a lot of paint.

Highlights of the PREP 3000™

The PREP 3000™ is a small-scale automotive prep station that can be customized in a number of ways. While it lacks the capacity to perform in the same manner as full-sized prep areas, you can modify it to increase its functions. Here are some benefits that set the PREP 3000™ apart from other compact prep areas:

- An additional work bay can be added.

- It comes with a powerful air system that supports spraying.

- You have the option of choosing between pitted and pitless designs.

- You can choose to use downdraft or modified downdraft technology.

- The PREP 3000™ supports drive-thru configuration so the automobile never leaves the work area.

Despite its small size, the PREP 3000™ provides a well-lit prep area that is easy to work in. A single turbine that is heavy duty and durable powers its exhaust system. If you choose to add the additional work bay, it will also use the same turbine.

A Prep Station Is Not a Paint Booth

Although your automotive prep station can be modified to support painting, it’ll never be the same as a proper paint booth. Automotive prep stations that provide limited finishing are able to spray up to a gallon of paint per eight hours. Anything more needs to be performed in a designated paint booth.

Whether you’re looking for a prep station or a fully operational paint booth, Accudraft has what you need to improve your performance. All of our products are industrial strength and durable, and they can perform at their best for thousands of working hours. Contact us to learn more about how our products can improve productivity and maximize the quality of your work.