How Accudraft Helps Body Shops During National Safety Month and Beyond

Since 1996, the National Safety Council (NSC) has celebrated National Safety Month during June. From safety engagement to risk reduction, the NSC has tons of free resources to help keep workplaces a safe environment not only during Safety Month but every day of the year. To support body shops and painters, Accudraft is a proud advocate for workplace safety and encourages everyone to follow the proper safety guidelines when spraying inside a paint booth.

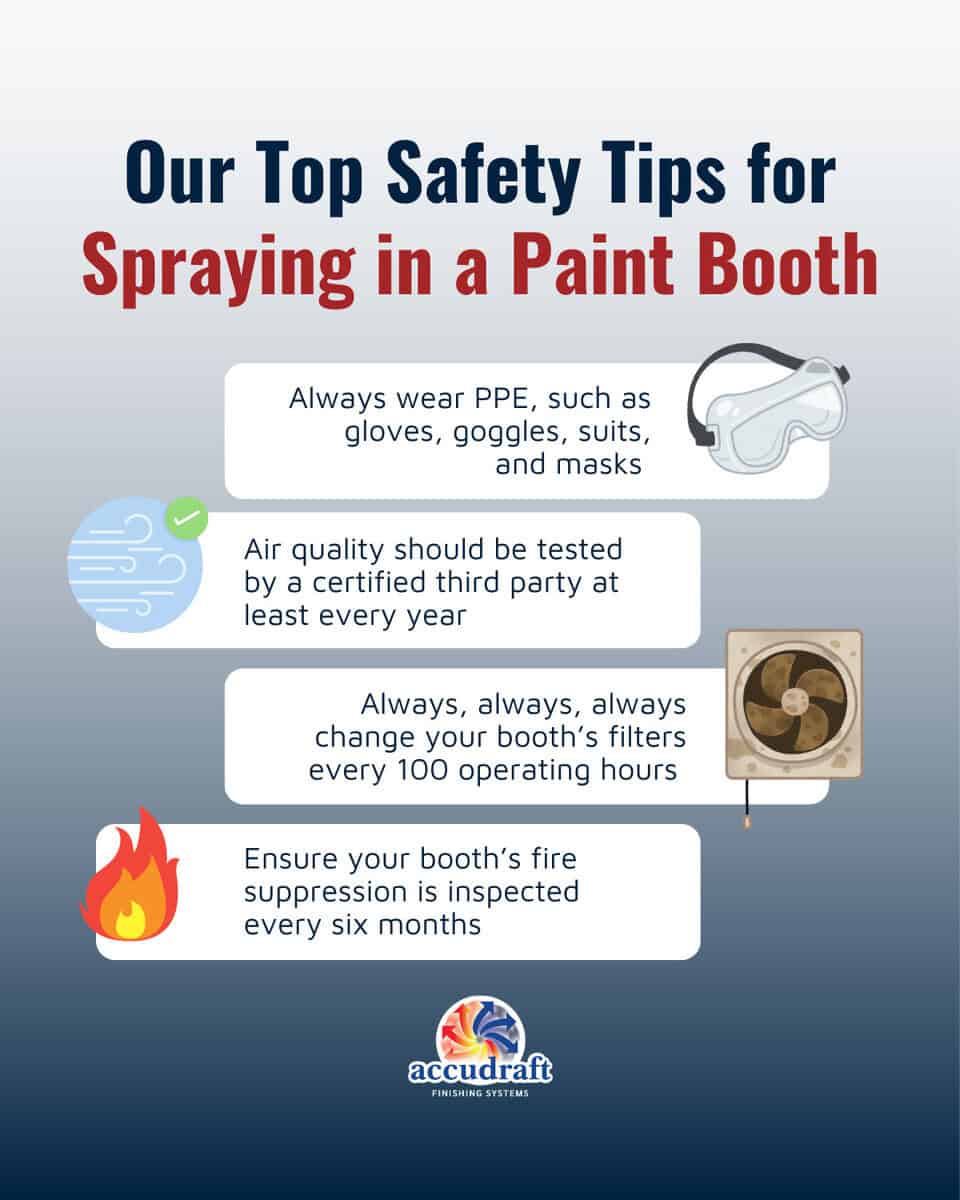

Our Top Safety Tips for Spraying in a Paint Booth

Always Wear PPE

Personal protective equipment (PPE) should always be worn when spraying inside of a paint booth. We’re talking gloves, goggles, suits, and masks—the full getup. While some painters may see PPE as an extra step or a chore, it’s beyond crucial to wear every time to prevent life-threatening health issues. Spray coatings emit VOCs (volatile organic compound) into the air during the drying process, which can cause skin irritation, headaches, loss of coordination, and internal organ damage when exposed to for long periods of time. Bottom line: always wear your PPE!

Test the Cabin’s Air Quality Regularly

Speaking of VOCs, there are many harmful air particles that float around the cabin during the refinishing process. It’s important to stay regular with air quality testing, at least once every year, to ensure that the booth’s airflow and filtration is properly containing all harmful emissions. In some cases, it may be beneficial to conduct routine exposure tests on painters to ensure their health isn’t being affected by VOCs and other chemicals.

Change the Filters

Every 100 operating hours, all booth filters should be changed—from the floor and walls to the ceiling and AMU. As air quality tests are typically only completed on an annual basis, it’s extremely important to stay on top of filter replacements throughout the year. Filters are a painter’s additional defense against VOCs, after PPE, but they only work as well as they are clean.

Ensure Fire Suppression is Up to Date

Every six months a paint booth’s fire suppression should be inspected to stay compliant with NFPA 33. Those are standard requirements provided by the National Fire Protection Association (NFPA) to mitigate fire and explosion hazards during the refinishing process while utilizing flammable or combustible materials and spray coatings.

Need Help Staying on Track? Call Accudraft

Between filter replacements and inspections, shops can lose track of hours and when to complete these essential tasks. With Accudraft LIVE, we’re only a tap and call away when something goes wrong. Our connected data platform allows shops to see the performance metrics of their booth, including time spent per phase, booth, and employee. It also alerts when it’s time to replace filters and parts, and shops can order them directly through LIVE. If your shop prioritizes safety in the workplace, investing in LIVE is a must. Contact Accudraft today to inquire about adding it to your booths.