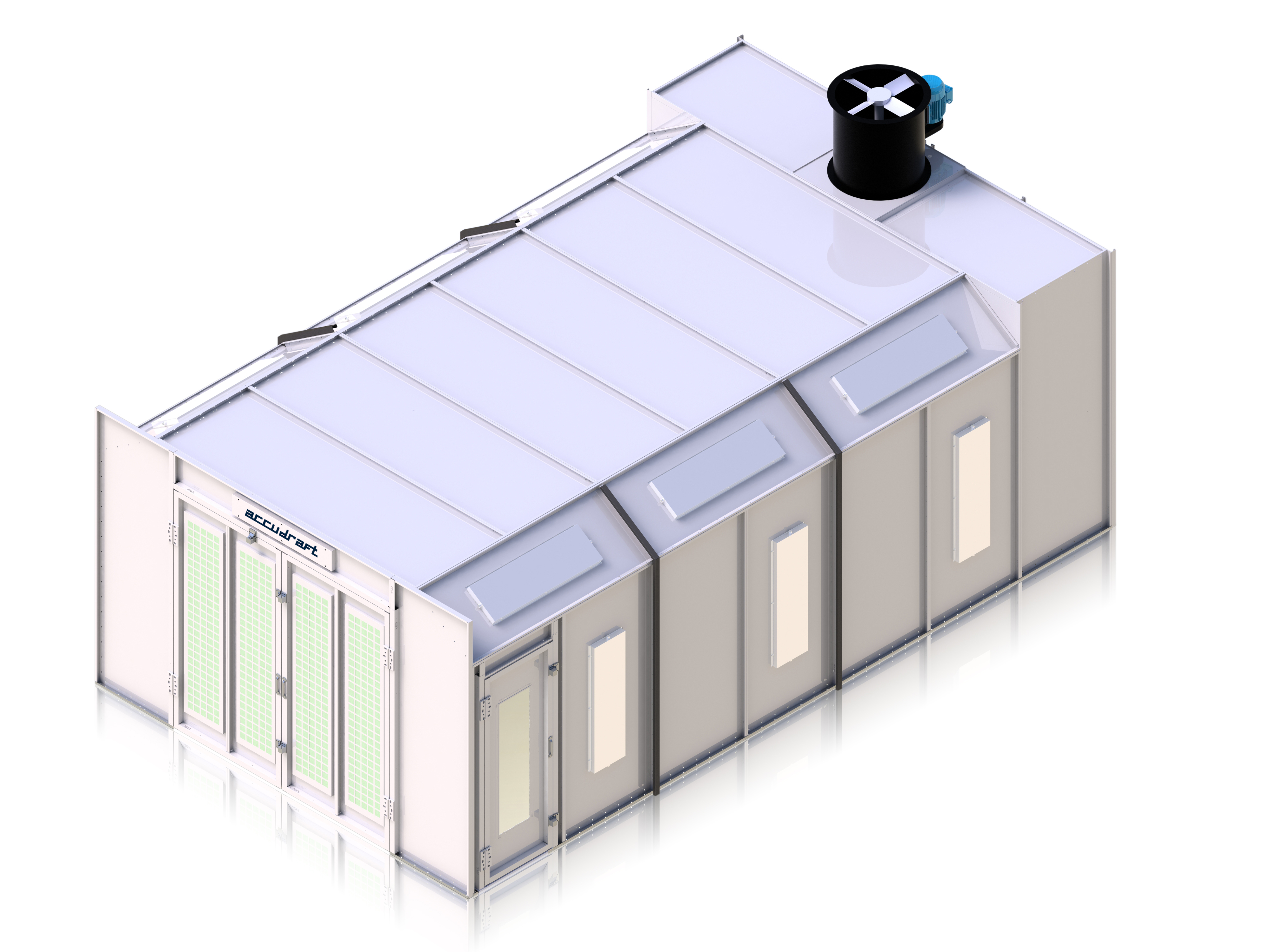

Crossflow

Air enters the front of the paint booth, flows along the length of the cabin and is exhausted out the rear of the paint booth. Shown below with white on white finish option.

*Click image below to view specs*

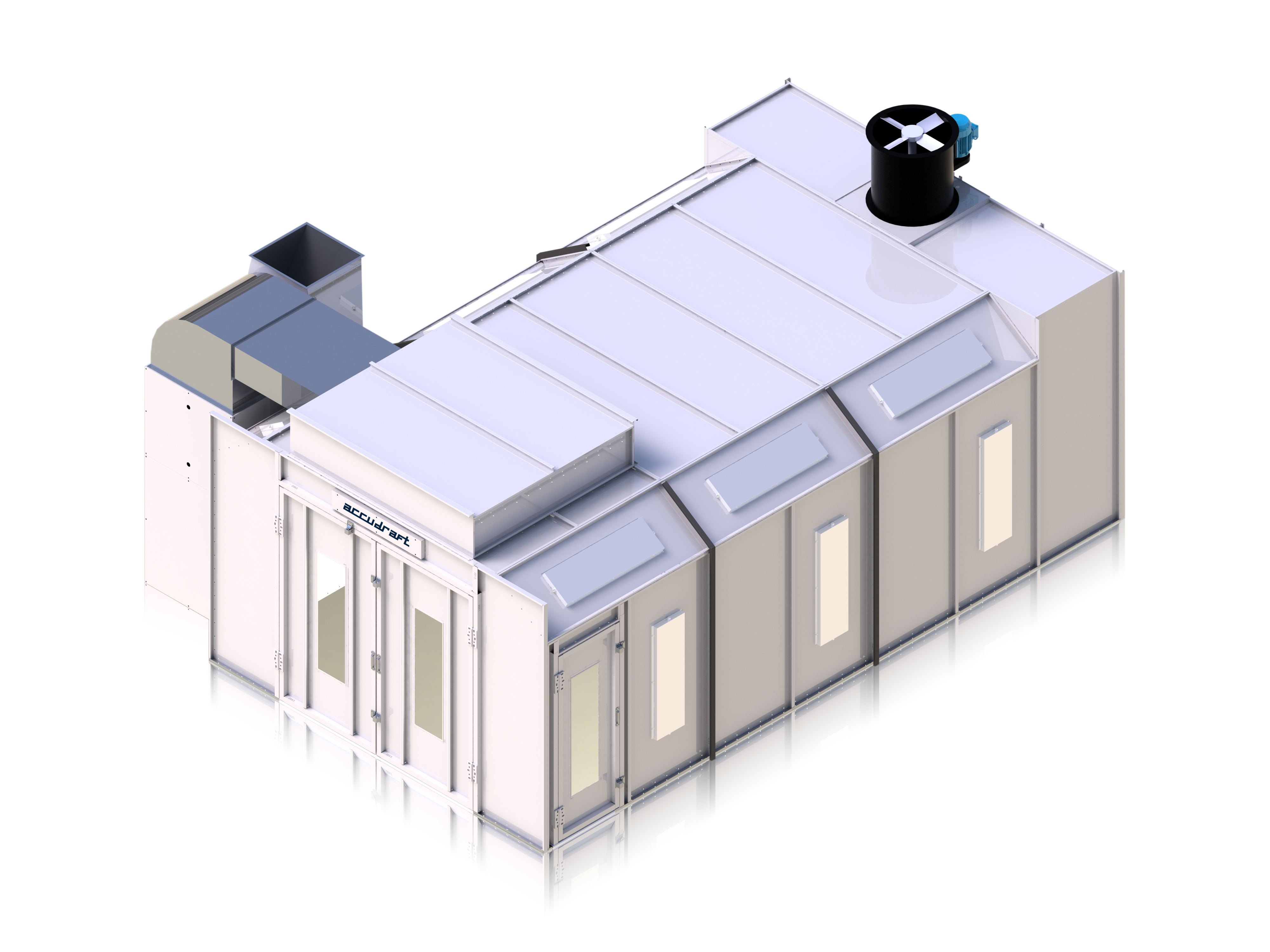

Semi Downdraft

Also known as a modified downdraft paint booth or simply “semi down paint booth”. Air enters the ceiling of the paint booth, flows along the length of the cabin and is exhausted out the rear of the paint booth. Shown below with optional heating system and white on white finish option.

*Click image below to view specs*

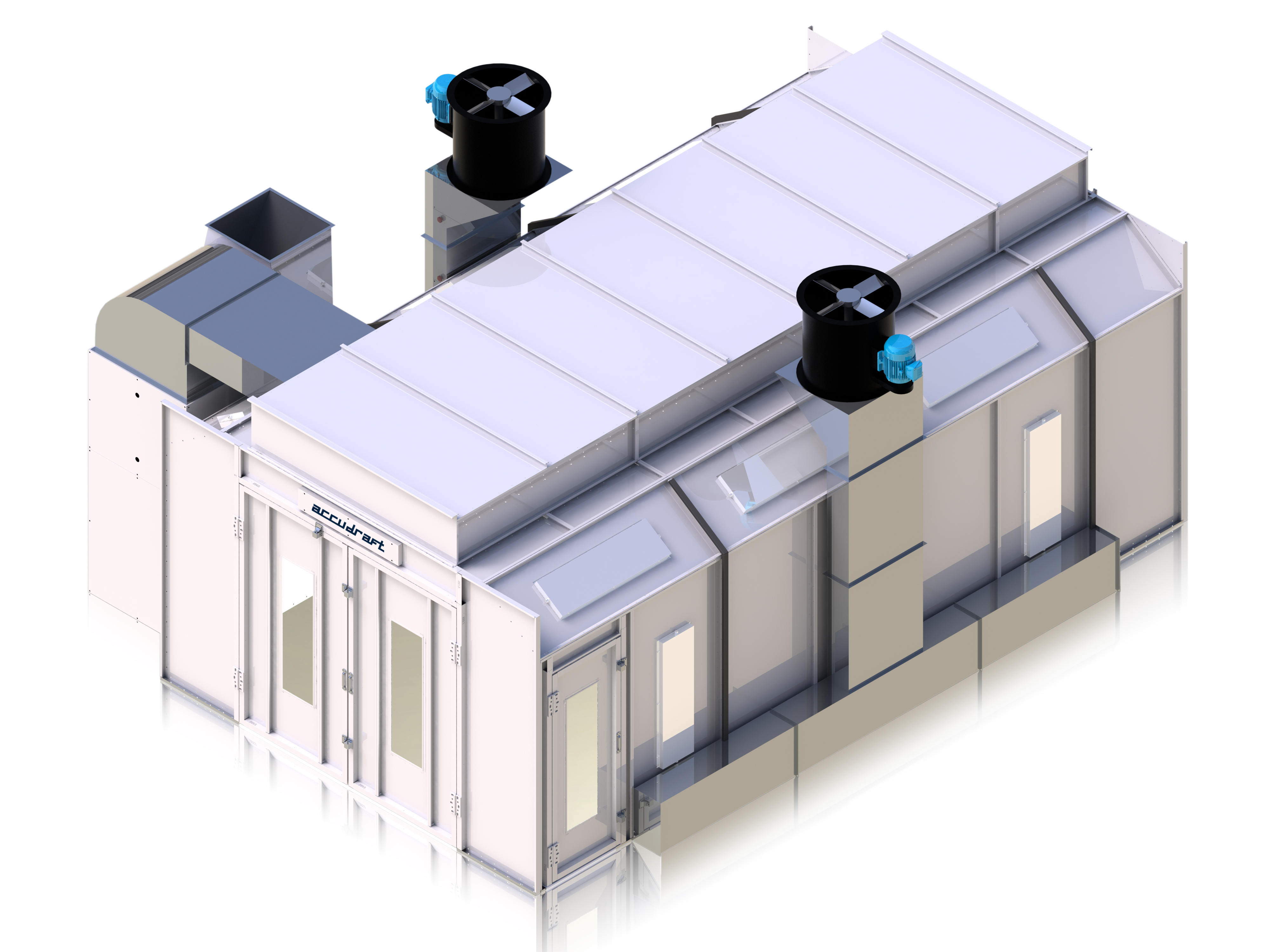

Side Downdraft

Also known as a “side draft” or “side down” paint booth. Air enters the ceiling of the paint booth, flows downward from ceiling to floor and is exhausted out the side walls. Shown below with optional heating system and white on white finish option.

*Click image below to view specs*

Spark Proof Tube Axial Exhaust Fan

Spark-proof construction allows this fan to exhaust hazardous or explosive gases. Regreasable ball bearings provide easy maintenance from outside the fan body extending usable life and performance.

Paint Booth Controls

ETL listed paint booth controls include all fan motor and light contacts with thermal overload protection on every circuit. Filter pressure gauge, solenoid, and air flow switches included.

SmartPad™ Digital Controls

Accudraft’s SmartPad™ digital control panel provides the user with all process information and settings in one compact and easy to read paint booth control unit. Choose between solvent and waterborne paint modes before you start. All processes are then automatic for that type of paint. The SmartPad™ can also integrate Accudraft’s Xcelerator™ for the ultimate in paint drying speed.

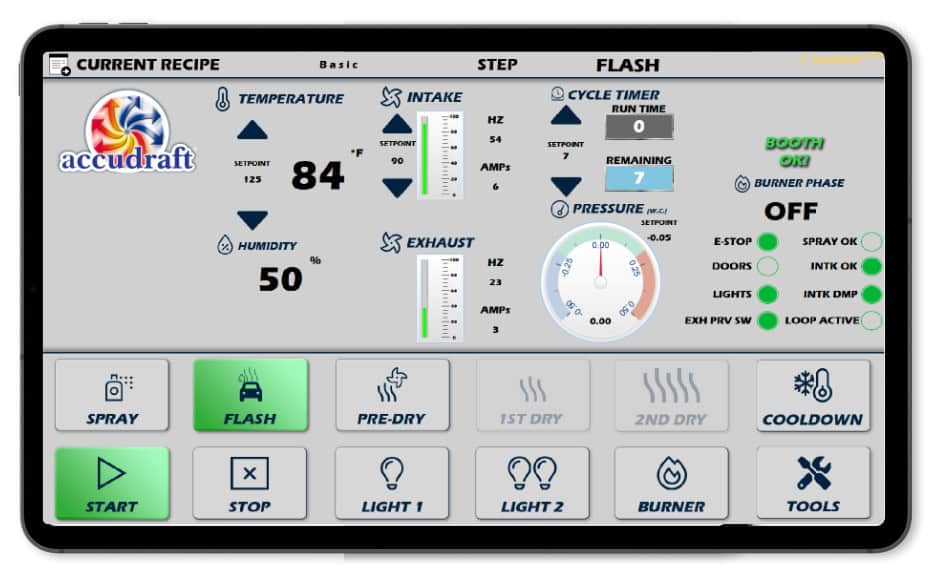

LIVE™ 15″ Touchscreen Control Panel

LIVE™ is an upgrade that allows the user to configure up to 999 separate programs, each set to your preferences or according to the coating manufacturer’s recommendations.

- Easy to use touchscreen monitor

- Quickly and easily change modes during painting operation

- Change the time, temperature, and airflow quickly from the home screen

- Monitor humidity, temperature, and other key data

- Filter life monitoring

- Filter change notifications

- Remote diagnostics and monitoring to reduce downtime

Accudraft’s LIVE™ Control Panel supports online support & services. Tech support can access any LIVE™ system and monitor operations in real time.