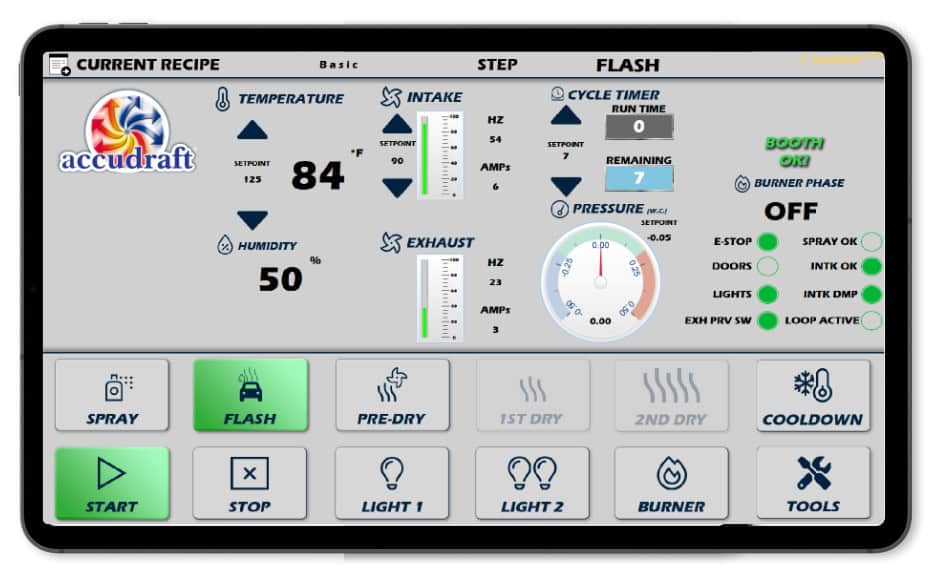

LIVE™ is Accudraft’s 15″ touchscreen control panel that includes every capability of Accudraft’s SmartPad panel plus internet connectivity for unprecedented information recording and unlimited future capabilities. With the addition of internet connectivity, LIVE™ allows users and Accudraft to understand what is happening with any given system anywhere in the world.

Updates to Software

LIVE™ will allow the user to update the software as they become available. If new features are added or a bug is fixed, an update will appear, and the user will be prompted to update the software. This will keep the paint booth controls up to date with the latest programs and upcoming demands from coatings manufacturers.

Remote Monitoring and Intervention

LIVE™ has a unique IP address, and Accudraft can log in to any machine in the world. This is not to be confused with a simple monitoring service, which only lets Accudraft techs see what is happening. Our LIVE™ panel allows the technician to see what is happening and operate the unit remotely. This certainly does not eliminate the need for on-site service, but it is invaluable when a technical problem exists, and routine tests could point to a simple problem. At the very least, a technician will be dispatched with much more information on the issue than without LIVE™.

Job Costing

LIVE™ paint booth control panels keep all your information saved per job. Now, you’ll see how much energy and time the paint booth used when finishing a truck or part. This information is available both locally at the paint booth controller and on your Accudraft account online.

Filter Ordering Right from Your Control Panel

Meet the functionality that will change the way you service your paint booth. Time alarms and running hours are directly reported to Accudraft, so we know how your system functions and what it needs, when it needs it. Every facility is different, and usage determines the frequency of service and filter changes for your truck paint booth.

The LIVE™ paint booth control panel does all the thinking for you. If you need filters right away, no need to go anywhere else; order filters directly from the LIVE™ touch screen, and they will be processed immediately. No need to measure filters or give any information to us. Your machine specs are saved in our database, and the correct filters will arrive at your doorstep.